3 Axis DRO Installation – New life for our 1974 Bridgeport

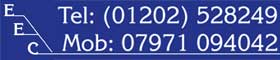

Many thanks to Gary and Kris from EEC Ltd, for the fitting & installation of a new ACU-RITE 203 – 3 Axis DRO System, to our Bridgeport Mill.

The replacement of an ailing Sony Magnascale setup has resulted in a new enthusiasm in the workshop. As can be seen from the photos EEC Ltd made an excellent job of the installation. Gary and Kris were professional, helpful and supportive throughout the process.

I have no hesitation in recommending EEC Ltd for their work,

Tony, Somerset Machining

DRO for Bridgeport Mill. X, Y and Z axis Acu-Rite SENC 150 linear scales fitted with using bespoke brackets and guards

Specifications |

ACU-RITE DRO 203 |

|

Application |

Milling, turning, grinding, boring and general purpose |

|

Axes |

2 or 3 from A to Z and Z0 |

|

Encoder Inputs |

TTL |

|

Display step |

|

|

Display |

|

|

Status Display |

|

|

Axis Display |

Standard |

|

Common Functions |

|

|

Turning Specific Functions |

|

|

Milling Specific Functions |

|

|

Cycles |

Oblique line, circular arcs; only for milling, drilling, boring:circular and linear hole patterns |

|

Error Compensation |

|

|

Data Interface |

USB 2.0 type C

|

|

Options |

|

|

Electrical Requirements |

AC 100 V to 240 V (±10 %), 50 Hz to 60 Hz (±5 %), ≤ 33 W |

|

Operating Temperature |

0° to 45º C (32º to 113º F) |

|

Protection EN60529 |

IP 40, Front Panel IP 54 |

|

Weight |

~1.9 kg |